Many of you know that I have been working with water reuse systems for some four decades now. One of the first projects was the development (and sale) of a home wastewater recycling system. During it’s development, we found that certain high use conditions led to a buildup of ammonia in the returning (clean) wastewater to the toilet. Trust me, there are only so many times you can tell the homeowner that the ammonia smell means their toilet bowl is clean. (If you must know, once was about the limit!)

Category Archives: Water

No fracking way!

I have been amazed that we have build many an ethanol plant in water short areas (like Florida). I have been even more amazed when these same facilities are not designed to reuse the water they employ, which would both save them money- and reduce their impact on the environment. Our numbers show these folks can increase their profits about 3 to 5 cents a gallon- after accounting for the cost of water treatment- by incorporating water reuse.

It’s coming- to a faucet near you. (Hopefully, not too soon!)

Roy A. Ackerman

About every 10 years, this comes up again. But, at least over my lifetime, it never seems to get very far. Water reuse.

Continue reading It’s coming- to a faucet near you. (Hopefully, not too soon!)

Soon, not a drop to drink…

I’ve discussed on several occasions that the world’s next wars will be over water. Not only because we are running short of potable water, but because we are running short of water for almost all purposes. It doesn’t help matters that there is no international treaty that governs actions when waterways cross national boundaries. Typically, it means that downstream nations get the short straw.

You’ll never think of humidity the same way again

The next wars will be about water and not oil. Because potable water is becoming as short in supply as any of our precious metals. It’s an issue in the Middle East. It’s an issue in Africa. It’s an issue in Asia. It’s an issue in the Western portion of the United States. It’s even an issue in Virginia and Florida.

Continue reading You’ll never think of humidity the same way again

If we don’t stop these practices, we won’t have viable antibiotics

We have a real problem. Our antibiotics are becoming less effective against microbes. The reason is simple- the bacteria (to paraphrase from the King and I) have become accustomed to your face- they have begun mutating to make themselves invulnerable to the actions of the antibiotics. The source of this problem is also simple- it’s us.

Continue reading If we don’t stop these practices, we won’t have viable antibiotics

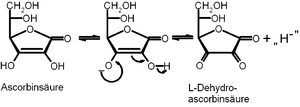

Ascorbic Acid IS a most useful chemical (that’s Vitamin C for the non-scientists)

Bicarbonate Dialysis is better (Dialysis, part 3)

That earlier choice of acetate as the dialysate buffer is now (very early 80’s) becoming a problem. Oh, it was great when dialysis was slow (12 hours) and had “tight” membranes; but, now, with the more efficient membranes and shorter dialysis, the saw-tooth pattern that existed for toxins is now occurring for our blood buffer. During dialysis, the acetate replaces the bicarbonate buffer; after dialysis, the acetate is slowly converted to bicarbonate. Obviously, this is not the best situation for patients.

Continue reading Bicarbonate Dialysis is better (Dialysis, part 3)

Cement- a major source of carbon dioxide emissions and water usage- redefined

Many of you know that MIT is one of my almae matres. I chose it both due to a personal reason (my ex-wife was accepted to BU) and because it was the antithesis of my undergraduate haunts. Brooklyn Poly basically taught one how to make things work (and minimized the theory). MIT was “gung-ho” on the theoretical aspects and less interested in real-life situations. I melded both of those attitudes into a balanced approach to engineering/business issues. Well, I just attended an MIT event that – at least for these disciplines- demonstrated that MIT is now interested in both.

MIT Professor Franz Ulm described his work with concrete. This is the most widely used man-made material in the world. Cement is among the oldest engineered construction materials, dating back to the Roman Empire (remember seeing all those extant aqueducts?). It basically starts out as limestone and clay mixtures that are then crushed into powder, and then subsequently heated to a very high temperature (1500 C) in kilns. This forces transformation of the materials, with tremendous potential energy bound into the powder. Upon mixing with water, the energy employed to bond the units into calcium-silicate-hydrate (C-S-H) complexes. . (Cement is NOT a molecule; while one could consider the composition to be (CaO)1.65(SiOs)(H2O)1.75, this is an approximation. ) At the microscopic level, these CSH units serve as a binder for the added sand and gravel ; this mixture is the concrete. Most of the carbon dioxide emissions in this manufacturing process result from heating the kiln to a temperature high enough to transfer energy into the powder. (Limestone is CaCO3; the heating removes the CO2 and the calcium oxide (CaO) is the active unit in the precursor)

There are some 25000 million tons of cement produced annually; all metals only account for 1350 million tons. More importantly in light of our desire to lessen our carbon footprint, this represents 32.5 billion GJ (gigaJoules) of energy, compared to 26.5 for metals. (And, notice how much MORE energy is required for the production of those metals.) This is equivalent to the power produced by some 700 nuclear power plants. There is one (1) cubic yard of concrete for each person on earth and 5% (some say 10%) of the earth’s CO2 emissions results from concrete manufacture.

Another way of looking at this is that 8 tons of concrete or 1 ton of cement is equivalent to 1 ton of carbon dioxide. If we could cut the carbon dioxide use by altering our cement technology, we could go a long way to solving our carbon crisis. This is even more critical when one recognizes that we are currently using some 3200 million tons of timber, while the earth is creating 2500 million tons a year.

If we converted all our heating to clean energy and sequestered carbon dioxide (solar, wind, etc.), our carbon dioxide emissions in 2050 will be on par with those of 2005- not much change. If we improved our concrete production technology, we would REDUCE our impact by 83% compared to 2005. It was estimated that if Europe (or America) would impose a carbon tax of $ 40/ton, it would wipe out concrete production in those areas, since it would be cheaper to import the concrete from Egypt.

By improving the strength of our concrete, we could reduce the size of our concrete beams and columns. There is an inverse relationship between size and strength for columns and perfect shells; the relationship for beams is X to the -2/3 power [ed:Â NO superscripts seem to work here] . If we double the strength, we halve our carbon dioxide usage.

The process that he discussed involves ordering the atoms. (Remember, cement is NOT a molecule- see above) ; while one could consider the composition to be (CaO)1.65(SiOs)(H2O)1.75, this is an approximation. ) Normal concrete has a random structure; if we order it to make it more closely compacted (from 64% of volume to 74%), the strength is radically improved. [Although this was not discussed, these numbers closely match how crystals exist in nature. The most common structure is body centered cubic, which has a packing factor of about 68%; face centered is 74% packed.]

Even with all of these factors, the best approach is not for universal changes in concrete production, since there is a higher need for quality control and more skilled workers. The best approach for this use is in precast concrete used for bridges and special buildings. One example he cited was the Jakway Park Bridge In Iowa. This bridge used precast concrete 7.5 cm thick- instead of the normal 20 cm or so thick beams.

In addition to ordering the atoms to be more closely packed, the discussion included the incorporation of fibers and nanoparticles of titanium dioxide. The former usage increases the durability dramatically; the latter provide an added environmental benefit. When you incorporate the TiO2 nanoparticles, the ultraviolet irradiation in sunlight activates the oxygen atoms at the surface to break down NOx molecules; reducing air pollution. (This technology is in use at the Jubilee Church, formally known as Dio Padre Misericordioso. In addition to the air pollution benefit, the TiO2 keeps the concrete white (aesthetically pleasing; titanium dioxide is how we get “white†paper) and the concrete maintains the temperatures more evenly.)

What was NOT discussed was the water needs for this new concrete. When I inquired, Dr. Ulm pronounced that this would reduce the water usage concomitantly. It should be noted that concrete is one of the largest consumers of water in industry; it is why most concrete facilities are near water sources and why water reuse projects have focused on just that industry segment, as well.